10,000-ton/Year Granulated Organic Fertilizer Rotary Drum Granulation Line Intro (Tạm dịch: Đường dây phân hạt trống xoay)

Dòng sản xuất hạt phân bón hữu cơ 10.000 tấn / năm là một dòng sản xuất tiêu chuẩn và tự động được thiết kế cho các doanh nghiệp sản xuất phân bón hữu cơ lớn và vừa.Nó sử dụng một granulator trống quay như là thiết bị hình thành lõi, và được trang bị thiết bị cho toàn bộ quy trình, bao gồm xử lý trước nguyên liệu thô, lên men, sấy khô, làm mát, sàng lọc và đóng gói.Nó có thể hiệu quả chuyển đổi nguyên liệu hữu cơ như phân gia súc và gia cầm, axit humic, và rơm thành phân bón hữu cơ hạt tiêu chuẩn đáp ứng các yêu cầu. Nó phù hợp với nhu cầu phân bón nông nghiệp quy mô lớn, cải thiện đất,và phát triển nông nghiệp xanh, và đạt được công suất sản xuất hàng năm ổn định 10.000 tấn (được tính trên cơ sở 300 ngày hoạt động mỗi năm và công suất sản xuất trung bình hàng ngày khoảng 333 tấn).

Giai đoạn quy trình và cấu hình thiết bị

Phần chế biến trước (cơ sở nguyên liệu thô)

2 bộΦ800 nhà máy búa (20-25 t/h): Chụp rơm/rác nấm đến≥80 mesh; nghiền nát lại phân gia súc/vật gia cầm lên kích thước hạt đồng nhất.

1 máy trộn 2 trục (5m)³,≤3 phút / lô): Trộn các vật liệu hữu cơ nghiền nát, chất điều hòa (bột zeolite / nhựa mài, 3% -5%) và các tác nhân vi khuẩn (đối với phân bón hữu cơ sinh học) đồng nhất≥95%.

Phần hạt nhân lõi (Đơn vị đúc chính)

1 bộΦ2.0×6Granulator trống xoay.0m (15-18 t / h, 37kW): Thích hợp cho công suất 100.000 t / a; lớp lót cao su chống mòn 30mm (kháng axit,≥Thời gian sử dụng 3 năm).

4 thiết bị liên kết phun chính xác (bột tinh bột / natri humate, thêm 2% -4%): Khối lượng phun được điều khiển bởi PLC, tỷ lệ hạt 85% -90%.

Điều khiển tốc độ tần số biến động (5-10 r/min): Điều chỉnh theo độ ẩm / độ nhớt của nguyên liệu thô; 333 t/d đầu ra bán hoàn thành.

Phần sau chế biến (Quality & Stability of Finished Product)

1 bộΦ3.2×Máy sấy xoay 12m (máy đốt hạt sinh khối, 18-20 t/h): Sấy hạt 30%-35% độ ẩm đến≤15% (chống nấm mốc trong quá trình lưu trữ).

1 bộΦ2.5×Máy làm mát ngược dòng 8m: làm mát 60-80°Chạt đến nhiệt độ phòng (ΔT≤5°C); độ bền hạt≥2.8N.

1 bộΦ1.8×4.0m màn hình trống (2-5mm/5-8mm lớp kép): phân loại hạt;≤Bột mịn 2mm tái chế, các hạt đủ điều kiện 2-8mm đi vào bao bì; hiệu quả sàng lọc≥18 t/h, tỷ lệ đào tạo≥98%.

Phần phụ trợ & đóng gói (Sản xuất liên tục & Lưu trữ thuận tiện)

Máy thu bụi túi xung (20.000 m)³/h): Thu thập bụi từ nghiền / sấy / sàng lọc; phát thải≤10mg/m³(đối với GB13271-2014).

2 máy đóng gói định lượng tự động (25kg/50kg túi, 400-500 túi/giờ): Được trang bị dây chuyền vận chuyển và robot làm phẳng; đóng gói tự động / làm phẳng, giảm chi phí lao động.

Hỗ trợ và Dịch vụ:

Tại Tianci Heavy Industry Machinery, chúng tôi cam kết cung cấp hỗ trợ và dịch vụ hoàn chỉnh để đảm bảo mọi khách hàng đạt được kết quả tốt nhất từ thiết bị của chúng tôi.Từ lập kế hoạch dự án đến bảo trì sau bán hàng, đội ngũ của chúng tôi cung cấp hỗ trợ chuyên nghiệp ở mọi giai đoạn.

1Tư vấn trước bán hàng

Chúng tôi giúp khách hàng lựa chọn các máy phù hợp nhất theo vật liệu, công suất và nhu cầu sản xuất của họ.Thiết kế tùy chỉnh và các giải pháp kỹ thuật có sẵn để đáp ứng các yêu cầu cụ thể của dự án.

2Thiết lập và đào tạo

Các kỹ sư có kinh nghiệm của chúng tôi có thể hướng dẫn lắp đặt tại chỗ hoặc trực tuyến. Chúng tôi cũng cung cấp hướng dẫn hoạt động chi tiết và đào tạo để đảm bảo khởi động sản xuất suôn sẻ và hiệu quả.

3Dịch vụ sau bán hàng

Chúng tôi cung cấp hỗ trợ kỹ thuật lâu dài, cung cấp phụ tùng thay thế nhanh chóng và hướng dẫn bảo trì thường xuyên. Bất kỳ vấn đề nào cũng được giải quyết kịp thời để giảm thiểu thời gian ngừng hoạt động và giữ cho sản xuất của bạn hoạt động ổn định.

4. Hỗ trợ toàn cầu

Với các dự án thành công ở hơn 200 quốc gia, chúng tôi hiểu nhu cầu của các thị trường khác nhau và cung cấp dịch vụ đáng tin cậy bất kể bạn đang ở đâu.

Tại Tianci, nhiệm vụ của chúng tôi không chỉ là cung cấp máy móc chất lượng cao mà còn xây dựng quan hệ đối tác lâu dài thông qua sự tin tưởng, tính chuyên nghiệp và hỗ trợ liên tục.

Máy nén trống xoay Câu hỏi thường gặp (FAQ)

Hỏi: Ông có thể chỉ định phạm vi đầu ra hàng giờ của máy hạt trống của ông?

A: Nếu bạn có nhu cầu sản lượng cao hơn (ví dụ, hơn 25 tấn mỗi giờ), bạn có thể sử dụng các máy nén.chúng tôi có thể tùy chỉnh một giải pháp tùy chỉnh dựa trên nhu cầu sản xuất cụ thể của bạn.

Hỏi: Làm thế nào để một máy nén trống quay hoạt động?

A: Một máy cắt hạt trống hoạt động bằng cách làm sập vật liệu trong sự hiện diện của chất kết nối lỏng để khuyến khích hình thành và tăng trưởng hạt.Hành động lăn, kết hợp với độ dính từ chất kết dính, làm cho các hạt mịn tập hợp lại thành các hạt. Những hạt này tiếp tục nhận thêm các hạt mịn và chất kết dính khi chúng rơi xuống giường,làm cho chúng trở nên dày đặc và thu thập thêm các lớp trong một hiện tượng được gọi là hợp nhất. Chuyến bay tumbling có thể được kết hợp vào đơn vị để tăng sự khuấy động của giường vật liệu.

Cách hình thành axomerat này là một loại axomerat kích thích còn được gọi là hạt ướt, hình bóng hoặc pelletizing.

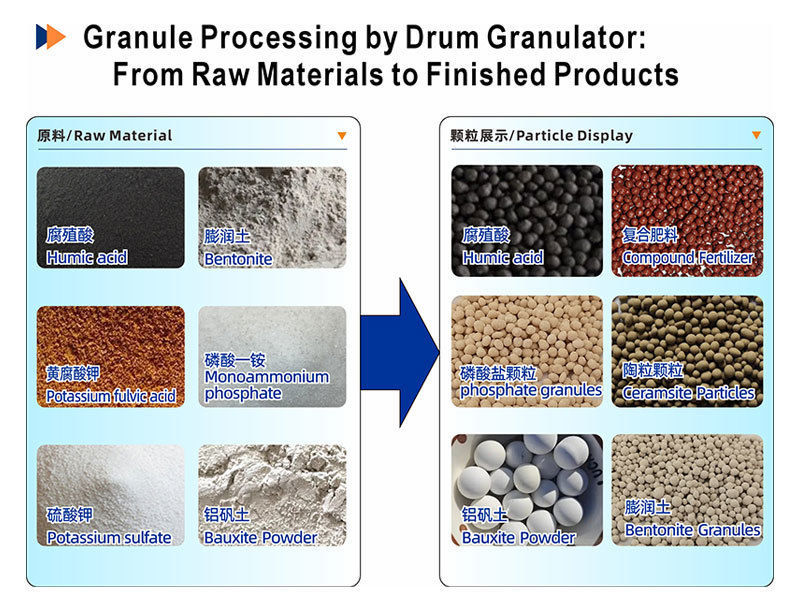

Hỏi: Những loại vật liệu có thể một máy viền Rotary?

A: Nói chung, máy hạt trống có thể xử lý bất kỳ chất rắn lớn nào dưới dạng bột mịn khô.vật liệu chế biến từ hóa chất đặc biệt và phân bón, đến khoáng sản và quặng, và mọi thứ ở giữa.

Trong một số trường hợp, nguyên liệu thô có thể yêu cầu xử lý trước dưới dạng nghiền nát, nghiền hoặc sấy khô để trở thành một thức ăn thích hợp cho máy hạt và tạo ra các đặc điểm mong muốn trong sản phẩm cuối cùng.

Hỏi: Ưu điểm của một granulator trống quay trên một disc pelletizer là gì?

A: Trong việc lựa chọn giữa máy hạt trống và máy hạt đĩa, trống thường được chọn vì nó cung cấp hiệu suất cao hơn so với máy hạt đĩa.Các trống quay cũng có lợi thế là một hệ thống đóng, có nghĩa là phân hạt xảy ra bên trong một môi trường kín, do đó vật liệu chạy trốn là hạn chế.

Một trống hạt có thể chứa bao nhiêu dung lượng?

A: Các thùng phân hạt có thể được tùy chỉnh gần như bất kỳ kích thước nào, chứa dung lượng từ 500 lb / hr 3500 TPH +.

Các máy hạt trống là hàng loạt hay liên tục?

A: Máy hạt trống quay thường được sử dụng trong một thiết lập liên tục, mặc dù chúng có thể hoạt động như một thiết bị lô trong một số môi trường R & D, chẳng hạn như Trung tâm đổi mới TIANCI.

Hỏi: Thời gian giữ lại của máy hạt trống quay là bao nhiêu?

A: Thời gian giữ lại là một thông số quy trình được sử dụng để kiểm soát các đặc điểm và chất lượng của vật liệu ra khỏi trống, vì vậy nó có thể thay đổi đáng kể tùy thuộc vào các mục tiêu quy trình và sản phẩm.Nói chung, thời gian giữ lại trong một granulator có thể giảm bất cứ nơi nào từ 30 giây đến 60 phút.

Hỏi: Những đồ đạc thường được mặc là gì?

A: Máy hạt trống xoay thường có bảo trì thấp, nhưng một số mặt hàng có thể bị mòn, tùy thuộc vào điều kiện hoạt động, và đặc biệt là nếu trống rơi ra khỏi đường thẳng.Các mặt hàng mòn phổ biến nhất cho một máy hạt trống thường bao gồm lớp lót (nếu có), bay lật (nếu có thể), và có thể là bánh xe trunnion, lốp xe và cuộn đẩy.

Sự sắp xếp trống quay là một khía cạnh quan trọng của bảo trì trống để ngăn ngừa sự hao mòn của lốp và bánh xe trunnion.khuyến khích mặc không phù hợp.

Hỏi: Sản phẩm ra khỏi máy hạt có cần phải khô không?

A: Vì quá trình hạt dựa trên chất kết dính lỏng để hình thành và lớp hạt,sản phẩm ra khỏi hạt mốc ướt và phải được sấy khô trừ khi nó được chuyển ngay đến một quá trình hạ lưu không đòi hỏi phải sấy khô (như trong trường hợp của quặng sắt, nơi các viên đá đi đến lò nướng).

Việc sấy khô thường được thực hiện trong máy sấy xoay, làm tròn và "mượt" các hạt như là kết quả của hành động lăn xảy ra khi trống quay.

Hỏi: Làm thế nào tôi biết nếu một granulator trống quay là đúng cho ứng dụng của tôi?

A: Cho dù một máy hạt trống quay có phù hợp với một dự án nhất định hay không phụ thuộc vào các mục tiêu quy trình và sản phẩm cụ thể, chẳng hạn như công suất, mức độ kiểm soát các đặc điểm hạt,Các thông số sản phẩm, và nhiều hơn nữa.

Khi không rõ liệu một máy hạt trống có thể đáp ứng các mục tiêu của dự án hay không,thử nghiệm có thể được thực hiện trong Trung tâm đổi mới TIANCI để đánh giá quá trình và xác định cấu hình thiết bị phù hợp nhất.

Hỏi: Có cần thiết bất kỳ thiết bị khác để hỗ trợ một granulator trống quay?

A: Máy hạt trống đòi hỏi một hệ thống cho ăn và lấy để vận chuyển vật liệu vào và ra khỏi trống.Họ cũng thường yêu cầu màn hình và một mạch tái chế để phục hồi trên và dưới và tái chế chúng trở lại trong quá trình

Máy hạt trống cũng thường được theo sau bởi một máy sấy quay và trong một số trường hợp, có thể được đi trước bởi một máy trộn để cung cấp một nguyên liệu nguyên liệu đồng nhất cho đơn vị.

Hỏi: Hành trình thiết kế trông như thế nào?

A: Thiết kế máy hạt trống xoay thường bắt đầu với thử nghiệm để đánh giá tính khả thi của việc phân hạt vật liệu dự định và thu thập dữ liệu quy trình chính như phần trăm lấp đầy, thời gian giữ lại,Tốc độ trống và độ dốc, thiết kế hệ thống phun, và nhiều hơn nữa.

Sau khi thu thập được dữ liệu, các kỹ sư làm việc dựa trên điều này để kích thước trống và kết hợp bất kỳ tính năng hoặc sửa đổi cần thiết nào để sản xuất sản phẩm mong muốn ở công suất dự định.

Hỏi: Dữ liệu nào cần thiết để thiết kế một máy nén trống quay?

A: Một loạt các điểm dữ liệu là cần thiết để thiết kế các granulator. Cùng với một mô tả quy trình, các dữ liệu sau đây thường được yêu cầu:

Tại sao chọn chúng tôi?

Hỗ trợ và Dịch vụ:

Chúng tôi cam kết cung cấp cho khách hàng của chúng tôi với hỗ trợ toàn diện và dịch vụ đáng tin cậy.cũng như dịch vụ thử nghiệm miễn phí để đảm bảo hiệu suất máy tối ưu. Mỗi máy đi kèm với một bảo hành một năm cho hoạt động không lo lắng. Ngoài ra, chúng tôi cung cấp dịch vụ cài đặt miễn phí và đào tạo chuyên nghiệp,giúp nhóm của bạn nhanh chóng làm chủ thiết bị và đạt được sản xuất hiệu quả.